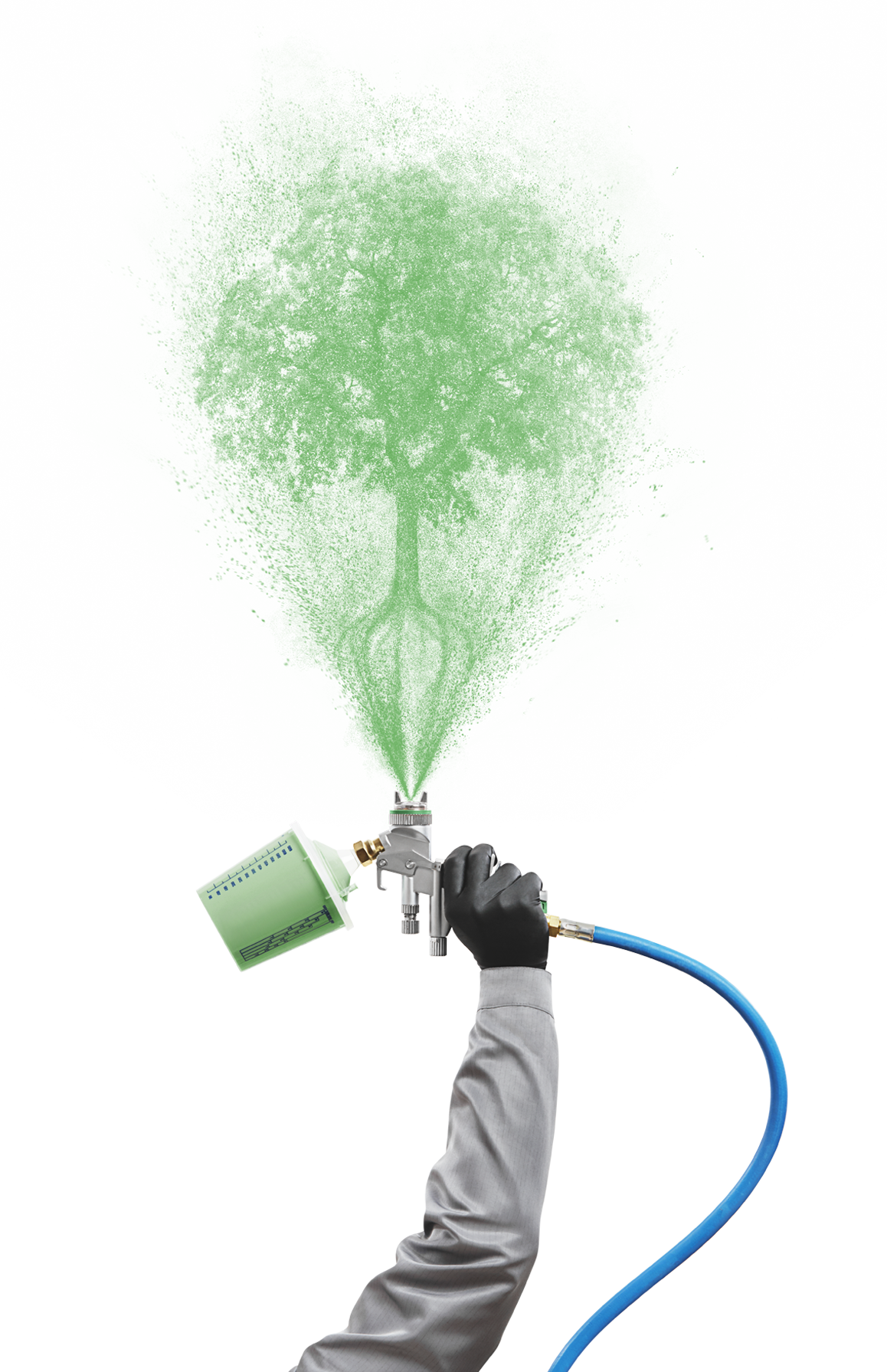

Bra för bilar och för miljön

Upptäck produkterna som både garanterar perfekta reparationslackeringar och är vänligare mot miljön, tack vare ett minskat utsläpp av CO2 i tillverkningsprocessen. Med R-M´s eSense-produkter ersätts fossila råvaror och fördelas matematiskt av förnyelsebart material. Ju större mängd eSense-produkter som våra samarbetspartners använder, ju mer bidrar vi alla till att förnyelsebart material används i framtiden.

Bläddra för att ta reda på mer om principen.

A brand of BASF –

We create chemistry

Tack vare eSense har vi sparat 2803.5t CO2, vilket

motsvarar 25,218,540 km*.

Upptäck en metod för

reparationslackering som skonar miljön.

*BASF product carbon footprints are calculated following general standards for life cycle assessment and product carbon footprints. The product carbon footprints are assessed cradle to gate, i.e. without CO2 emissions caused during product application and end-of-life treatment. Our product carbon footprint data is based on assumptions and approximations valid at the time of data collection. For more information, please visit https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/quantifying-sustainability/product-carbon-footprint.html eSense products contribute to reducing the use of fossil resources and reducing the CO2 emissions via the biomass balance approach. For our biomass balance products, 100% of the feedstock required for these products have been replaced by renewable resources. All our eSense products are certified according to the RedCert² standard. (BASF certification number REDcert²-929-35346515). For more information, please visit https://www.redcert.eu. When reference is made to CO2 savings per traveled kilometer, a standard CO2 emission of 95 grams per travelled car kilometer is assumed. Here you can find more information about BASF’s biomass balance approach: https://www.basf.com/en/bmb

Bläddra för att ta reda på mer om principen.

En enkel beräkning...

Billacker består huvudsakligen av fossila resurser, bland annat naftalen.

Bläddra för att ta reda på mer om principen.

En enkel beräkning...

Billacker består huvudsakligen av fossila resurser, bland annat naftalen.

Mer förnybara resurser, mindre fossila resurser

Metoden innebär att vi kan ersätta en andel av de fossila resurserna i BASF:s produktion med förnybara.

Ju mer, desto bättre

Strategin med biomassbalans innebär att vi redan använder förnybara resurser som bionaftalen eller biogas från organiskt avfall eller vegetabiliska oljor tillsammans med fossila resurser vid tillverkning av våra basprodukter.

Bläddra för att ta reda på mer om principen.

Ju mer, desto bättre

Strategin med biomassbalans innebär att vi redan använder förnybara resurser som bionaftalen eller biogas från organiskt avfall eller vegetabiliska oljor tillsammans med fossila resurser vid tillverkning av våra basprodukter.

Ekvationen

Andelen biomassa fördelas sedan matematiskt till vissa kommersiella produkter enligt en certifierad metod.

Bläddra för att ta reda på mer om principen.

Ekvationen

Andelen biomassa fördelas sedan matematiskt till vissa kommersiella produkter enligt en certifierad metod.

Så här påverkar du

Det innebär att ditt köp direkt påverkar procentandelen helt förnybara resurser som går in i vår produktion.

Bläddra för att ta reda på mer om principen.

Så här påverkar du

Det innebär att ditt köp direkt påverkar procentandelen helt förnybara resurser som går in i vår produktion.

Identisk kvalitet

När du använder R-M eSense får du exakt samma höga kvalitet som du är van vid. Men du har hjälpt oss öka andelen förnybara resurser.

Being successful means being innovative.

Tack vare eSense har vi sparat 2803.5t CO2, vilket motsvarar 25,218,540 km*.

*BASF product carbon footprints are calculated following general standards for life cycle assessment and product carbon footprints. The product carbon footprints are assessed cradle to gate, i.e. without CO2 emissions caused during product application and end-of-life treatment. Our product carbon footprint data is based on assumptions and approximations valid at the time of data collection. For more information, please visit https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/quantifying-sustainability/product-carbon-footprint.html eSense products contribute to reducing the use of fossil resources and reducing the CO2 emissions via the biomass balance approach. For our biomass balance products, 100% of the feedstock required for these products have been replaced by renewable resources. All our eSense products are certified according to the RedCert² standard. (BASF certification number REDcert²-929-35346515). For more information, please visit https://www.redcert.eu. When reference is made to CO2 savings per traveled kilometer, a standard CO2 emission of 95 grams per travelled car kilometer is assumed. Here you can find more information about BASF’s biomass balance approach: https://www.basf.com/en/bmb

Bläddra för att ta reda på mer om principen.

Upptäck en metod för reparationslackering som skonar miljön.

Being successful means being innovative.

Tack vare eSense har vi sparat 2803.5t CO2, vilket motsvarar 25,218,540 km*.

*BASF product carbon footprints are calculated following general standards for life cycle assessment and product carbon footprints. The product carbon footprints are assessed cradle to gate, i.e. without CO2 emissions caused during product application and end-of-life treatment. Our product carbon footprint data is based on assumptions and approximations valid at the time of data collection. For more information, please visit https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/quantifying-sustainability/product-carbon-footprint.html eSense products contribute to reducing the use of fossil resources and reducing the CO2 emissions via the biomass balance approach. For our biomass balance products, 100% of the feedstock required for these products have been replaced by renewable resources. All our eSense products are certified according to the RedCert² standard. (BASF certification number REDcert²-929-35346515). For more information, please visit https://www.redcert.eu. When reference is made to CO2 savings per traveled kilometer, a standard CO2 emission of 95 grams per travelled car kilometer is assumed. Here you can find more information about BASF’s biomass balance approach: https://www.basf.com/en/bmb

Upptäck en metod för reparationslackering som skonar miljön.